At present, the new energy base project mainly in the desert and Gobi is being promoted on a large scale. The power grid in the desert and Gobi area is weak and the support capacity of the power grid is limited. It is necessary to configure an energy storage system of sufficient scale to meet the transmission and consumption of new energy. On the other hand, the climatic conditions in the desert and Gobi regions of my country are complex, and the adaptability of traditional electrochemical energy storage to extreme climates has not been verified. Recently, Azelio, a long-term energy storage company from Sweden, has launched an innovative R&D project in the Abu Dhabi desert. This article will introduce the company’s long-term energy storage technology, hoping to store energy in the domestic desert Gobi new energy base. Project development is inspired.

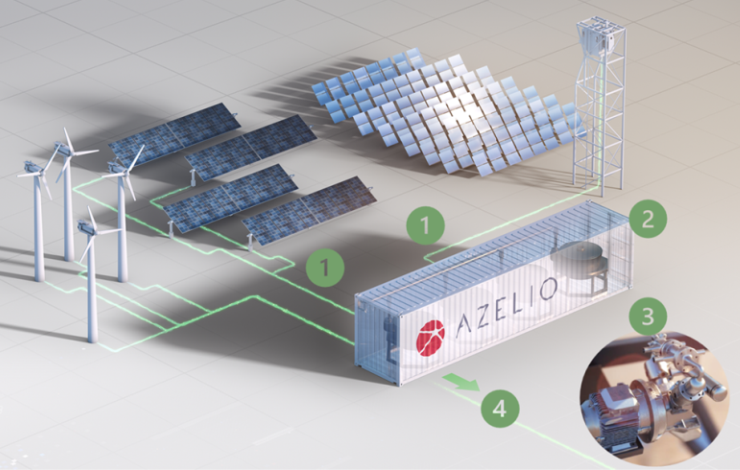

On February 14, the UAE Masdar Company (Masdar), Khalifa University of Science and Technology, and Sweden’s Azelio Company launched a desert “photovoltaic” project that can continuously supply power “7 × 24 hours” in Masdar City, Abu Dhabi. + Heat Storage” demonstration project. The project uses a recycled aluminum alloy phase change material (PCM) heat storage technology developed by Azelio to store energy in the form of heat in metal alloys made of recycled aluminum and silicon, and utilize Stirling generators at night Convert it into electrical energy, so as to achieve “7 × 24 hours” continuous power supply. The system is scalable and competitive in the range of 0.1 to 100 MW, with a maximum energy storage duration of up to 13 hours and a designed operating life of more than 30 years.

At the end of this year, Khalifa University will report on the performance of the system in desert environments. The system’s storage units will be demonstrated and evaluated against several criteria, including 24-hour supply of renewable electricity to an atmospheric water power generation system to capture humidity and condense it into usable water.

Headquartered in Gothenburg, Sweden, Azelio currently employs more than 160 people, with production centers in Uddevalla, development centers in Gothenburg and Omar, and locations in Stockholm, Beijing, Madrid, Cape Town, Brisbane and Varza. Zart has offices.

Founded in 2008, the company’s core expertise is the production and manufacture of Stirling engines that convert thermal energy into electricity. The initial target area was gas-fired power generation using GasBox, a combustion gas that provides heat to a Stirling engine to generate electricity. products that generate electricity. Today, Azelio has two legacy products, the GasBox and the SunBox, an improved version of the GasBox that uses solar energy instead of burning gas. Today, both products are fully commercialized, operating in several different countries, and Azelio has perfected and accumulated over 2 million operating hours of experience throughout the development process. Launched in 2018, it is committed to promoting TES.POD long-term energy storage technology.

Azelio’s TES.POD unit consists of a storage cell using recycled aluminium phase change material (PCM) that, in combination with a Stirling engine, achieves a stable discharge of 13 hours when fully charged. Compared to other battery solutions, the TES.POD unit is unique in that it is modular, has long-term storage capacity and generates heat while running the Stirling engine, which increases system efficiency. The performance of TES.POD units offers an attractive solution for further integration of more renewable energy into the energy system.

Recycled aluminum alloy phase change materials are used as heat storage devices to receive heat or electricity from renewable energy sources such as solar photovoltaics and wind energy. Store energy in the form of heat in recyclable aluminium alloys. Heating to around 600 degrees Celsius achieves a phase transition state that maximizes energy density and enables long-term energy storage. It can be discharged for up to 13 hours at rated power, and can be stored for 5-6 hours when fully charged. And recycled aluminum alloy phase change material (PCM) is not degraded and lost over time, so it is very reliable.

During discharge, heat is transferred from the PCM to the Stirling engine through a heat transfer fluid (HTF), and the working gas is heated and cooled to run the engine. Heat is transferred to the Stirling engine as needed, generating electricity at low cost and outputting heat at 55-65⁰ degrees Celsius with zero emissions throughout the day. The Azelio Stirling engine is rated at 13 kW per unit and has been in commercial operation since 2009. To date, 183 Azelio Stirling engines have been deployed around the world.

Azelio’s current markets are mainly in the Middle East, South Africa, the United States and Australia. In early 2021, Azelio will be commercialized for the first time at the Mohammed bin Rashid Al-Maktoum solar power plant in Dubai, UAE. So far, Azelio has signed a series of memorandum of understanding documents with partners in Jordan, India and Mexico, and reached a cooperation with the Moroccan Sustainable Energy Agency (MASEN) at the end of last year to launch the first grid-scale power plant in Morocco. Thermal Storage Verification System.

In August 2021, Egypt’s Engazaat Development S.A.E.Azelio purchased 20 TES.POD units to provide energy supply for agricultural desalination. In November 2021, it won an order for 8 TES.POD units from Wee Bee Ltd., a South African agricultural company.

In March 2022, Azelio entered the US market by installing the US certification program for its TES.POD products to ensure that TES.POD products meet US standards. The certification project will be conducted in Baton Rouge, Los Angeles, in partnership with MMR Group, a Baton Rouge-based electrical engineering and construction firm. The storage units will be shipped to MMR from Azelio’s facility in Sweden in April to accommodate U.S. standards, followed by a certification program installation in early fall. Jonas Eklind, CEO of Azelio, said: “U.S. certification is an important step in our plan to expand our presence in the U.S. market with our partners. “Our technology is ideally suited for the U.S. market at a time of high energy demand and soaring costs. Expand a reliable and sustainable energy supply. “

Post time: May-21-2022